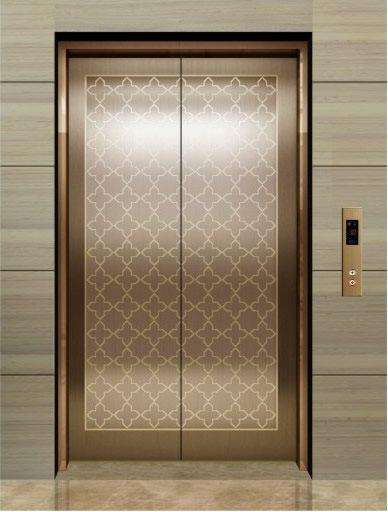

The continuous progress of society has brought us not only economic prosperity but also a refined aesthetic. In large shopping malls, hotels, and other public spaces, we can clearly see that elevators are no longer monotonous in color. Some elevator car panels have a mirror-like feel, while others feature patterns, creating a beautiful visual experience. This is what Dingliang Metal’s editor will discuss today: how mirrored stainless steel sheets are processed into elevator decorative panels.

Mirrored stainless steel sheets are used in elevator car panels. They are actually composite-surface stainless steel elevator decorative panels, made from an inner cold-rolled steel base plate and an outer stainless steel plate bonded together with strong adhesive to create a finished, conformable panel. The production method is as follows: first, prepare the materials, and cut the cold-rolled steel base plate and stainless steel panel in a quantitative manner according to the predetermined door panel size; create grooves, and use a groover to plan out a V-shaped groove with a depth of only 0.3 mm on the bending line of the base plate; after the base plate is phosphated, remove the grease and rust on the surface; apply glue to the non-grooved surface of the base plate and the surface of the stainless steel; dry the glue, and let the adhesive film applied on the two panels dry until it is no longer sticky; glue the accessories and door panel reinforcements to the two panels; finally, reinforce the door panel by welding without affecting the appearance.

Xinliheng en acier inoxydable

Xinliheng en acier inoxydable