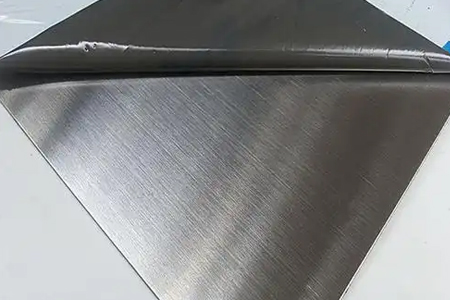

Among the many stainless steel processing techniques, brushing is unique and highly sought after. It involves directing abrasives such as abrasive belts and wheels onto the stainless steel surface, creating textured brush marks or lines.

Stainless steel brushing can create a variety of effects. Commonly used are straight lines, which create an uninterrupted pattern from top to bottom. This process is typically accomplished by moving the workpiece back and forth using a stationary brushing machine. A snowflake pattern, composed of regularly spaced dots, is a popular effect currently achieved using sandpaper. Nylon lines, composed of lines of varying lengths, are achieved due to the soft texture of nylon wheels, which can abrade uneven surfaces. Compared to other stainless steel finishing techniques, brushing offers significant advantages. For example, compared to polishing to create a mirror finish, brushing creates delicate, uniform lines, adding a modern, industrial aesthetic to stainless steel while avoiding the glare often associated with mirror finishes. This makes it particularly suitable for public spaces and outdoor applications. In terms of wear resistance, the subtle texture of a brushed surface effectively hides scratches and fingerprints, maintaining its appearance even in environments with high contact or friction. Smooth polished surfaces are more susceptible to scratches and stains. Regarding sandblasting, while both processes can alter the surface texture of stainless steel, the result is a relatively rough surface, while brushing creates a finer, more regular texture, offering a more decorative effect.

Brushed stainless steel has a wide range of applications. In the construction industry, brushed stainless steel is often used for elevator door panels, subway handrails, and escalator trim, offering both aesthetics and durability. In the building hardware industry, brushing enhances the product’s texture and improves its grip. In the kitchen, brushed stainless steel is used on range hoods, stoves, and sinks, making them easier to clean and maintaining their beauty over time. With its unique appearance, excellent wear resistance, pleasant feel, and wide applicability, brushed stainless steel stands out among other stainless steel processes, lending stainless steel products greater value and appeal.

Currently, Qingkong specializes in 300 series stainless steel: 304, 304L, 316L, 321, 309S, 310S, and 316Ti; 200 series stainless steel: J1, J2, J3, J4, E 201; 400 series stainless steel: 409L, 430, 410S, 439, and QES18 (for home appliances and elevators); duplex stainless steel: 2205, 2507, 2304, and S32001; and QN series stainless steel: QN1701, QN1801, QN1803, QN1804, QN1906, QN2109, QN2008, and QS380-MY (for the door industry). We offer stainless steel coils, plates, strips, and laser-cut parts, meeting your needs for flattening, slitting, frosting, mirroring, cutting, oil-brushing, sheet metal, and stamping.

The above is the content of this issue. If there are any shortcomings, please contact us.

Xinliheng Acciaio inossidabile

Xinliheng Acciaio inossidabile