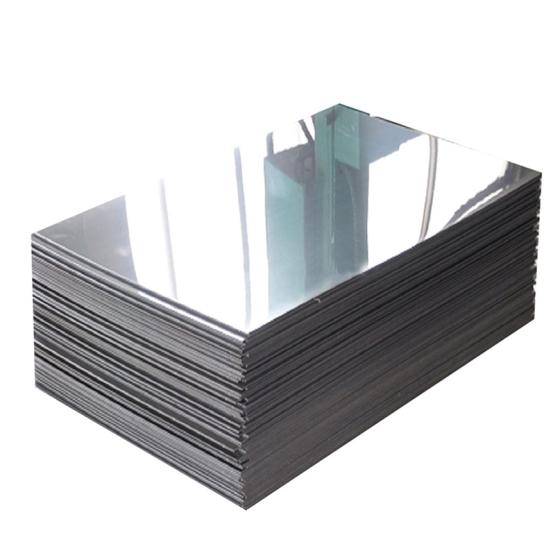

2B Stainless Steel Sheet – Smooth, Uniform, and Versatile

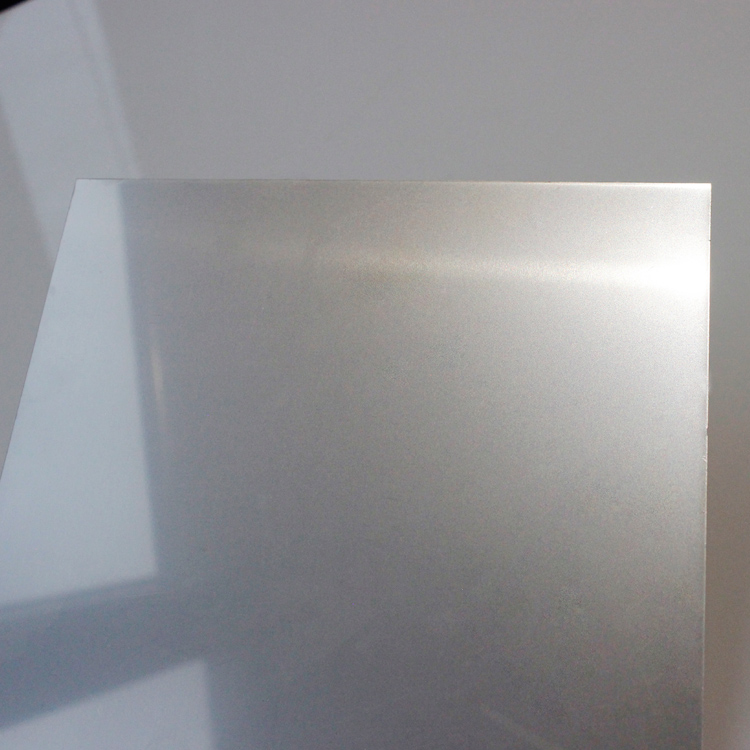

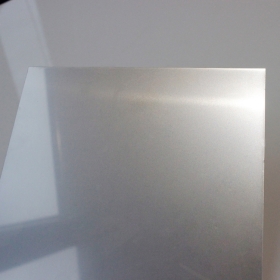

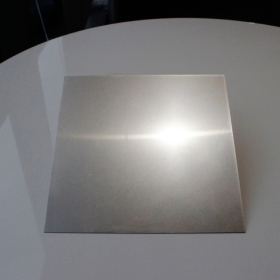

2B Finish Stainless Steel Sheet is the most widely used cold-rolled stainless steel surface in both industrial and commercial applications. After cold rolling, annealing, and pickling (or bright annealing), it undergoes a final skin-pass rolling to achieve a smooth, flat, and uniformly reflective surface with moderate luster — offering an excellent balance of appearance, formability, and cost-effectiveness.

Product Overview:

- Material Grades: SUS304, SUS316, SUS430, SUS310S, etc.

- Process: Hot-rolled slab → Cold rolling → Annealing → Pickling (or BA) → Skin Pass

- Surface Finish: Silvery-white, medium gloss, smooth, and flat

- Thickness Range: 0.3mm – 6.0mm (standard: 0.3–3.0mm)

- Width: 1000mm, 1219mm, 1500mm, 2000mm (customizable)

- Form: Coil or cut-to-length sheets

Key Surface Characteristics:

- Moderate gloss – between BA (high gloss) and No.1/2D (matte) finishes

- Excellent flatness and surface uniformity

- Ideal for secondary processing such as polishing, brushing, embossing, or coating

- Good drawability, weldability, and corrosion resistance

Typical Applications:

- Appliances: Refrigerators, ovens, washing machines

- Kitchen Equipment: Countertops, hoods, sinks, cabinets

- Food Service: Trolleys, prep tables, storage units

- Industrial: Enclosures, ducts, tanks, machinery

- Architecture: Interior walls, ceilings, partitions (often as base for further finishing)

- Transportation: Train interiors, container components

- Renewables: Solar frames, battery enclosures

Key Advantages:

- Cost-Effective – The go-to choice for general-purpose stainless use

- Excellent Workability – Easy to cut, bend, stamp, and weld

- Corrosion Resistant – Suitable for humid, sanitary, or mildly corrosive environments

- Versatile Substrate – Ideal base material for No.4 brushing, 8K polishing, PVD coating, etc.

Foshan Xinliheng stainless steel

Foshan Xinliheng stainless steel